ITC trains students for tech jobs

Feb 1, 2018

On the first day of classes, students searching for the Industrial Technology Center (ITC) may find themselves at the Innovative Teaching and Technology Center (ITTC) instead.

The ITC/ITTC confusion is common. Secluded on the south side of campus across University Avenue, the ITC is home to the Department of Technology.

“It’s not computer science, which most people think of when you say ‘technology,’” said Department Head Lisa Riedle. “They think of the computers and the cell phones. We are more industrial technology-based: manufacturing industry, graphics industry, construction management.”

“We’re engineering technology,” Riedle said. “So, if you look at understanding how a project gets done, you might have an engineer that designs it, and you might have the actual trades that build it. We’re the group in the middle [. . .] that helps get the job completed and to production.”

Currently, the technology department has about 500 students. Their six undergraduate programs are construction management, electrical engineering technology, technology and engineering education, technology management, graphic technologies and manufacturing engineering technology.

When the ITC was built in the mid-1970s, it was renowned nation-wide as a “technological marvel,” according to the Rod Library website.

In 1990, the 5,000 square-foot Metal Casting Center was added to the building, making UNI one of the few college campuses with an active foundry.

“This is a program that’s unique to the country,” said Scott Giese, a professor of technology. “We’re a world-premiere metal casting facility. People throughout Europe, Asia, North America, South America — we work with companies all across.”

Students in the manufacturing engineering technology program work in the foundry to complement their classwork.

“What we do in the Metal Casting Center is to practice the manufacturing process of what’s called liquid consolidation,” Giese said. “In basic terms, [. . .] you’re going to take a liquid and make it into a solid.”

This process works with metals and other areas like polymers and ceramics, explained Giese.

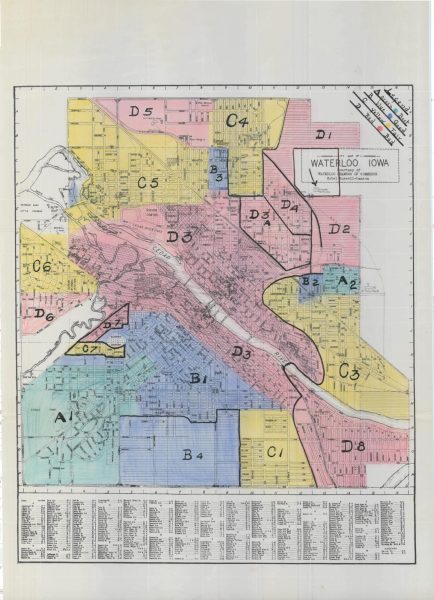

Combined with the Cedar Valley TechWorks facilities in Waterloo, which houses the largest 3D printer in North America, the Metal Casting Center employs 20 to 24 students each year.

One employee is Maria Alverio, a sophomore manufacturing engineering technology major. Alverio decided to do a metal-casting emphasis after watching Giese pour a mold during a lab.

“Seeing molten aluminum was one of the prettiest things I’ve ever seen in the entire world [. . .],” Alverio said. “It looked like a really shiny quarter or dime, but it was flowing like water, and it was so beautiful. I remember walking back to Campbell after that lab and calling my mom, telling her, ‘This is it! I’m going to be doing this for the rest of my life.’ So, then I got a job in the Metal Casting Center.”

Alverio described her work as similar to a lab assistant, testing the different properties of sand for various companies.

“Right now, we’re working on a […] project that’s looking at other sand materials that we can replace with our traditional sands,” Giese said.

Companies in the industry must meet new OSHA (Occupational Safety and Health Administration) standards regarding the amount of silica that can be inhaled; too much can cause silicosis, which occurs when the lungs are damaged due to inhalation of silicon.

“Someone had explained it to me like you’d have to have a salt packet, less than that in an entire football stadium,” Alverio said. “So that’s going to be really hard for foundries to meet because we use silica sand.”

Aside from conducting research, metal-casting students have created products like frying pans, bottle-openers, door knockers and even — non-working — cannons.

For another major in the technology department, the medium is not metal or sand, but ink and screens. Students in the graphic technologies program explore different aspects of the print and digital publishing industry and its workflows.

“There’s no industry that doesn’t deal with print, doesn’t deal with the digital communication,” said graphic technologies instructor Lee Geisinger.

Equipment in the graphic communication labs allow students to create canvas wraps, screen-printed shirts, vehicle wraps, laser engravings and more.

“I love the hands-on aspect,” said Adrian Mitchell, a senior communication studies and graphic technologies double major and president of the Grafx club. “It’s probably my favorite thing, just being able to create something that I know I am the producer of. I created it; I designed it.

“We made our own business cards, so we got to design a logo and we put them on a business card and cut them out,” Mitchell said. “So, I actually have a stack of business cards that I can hand out.”

While students are able to work on a variety of projects in the technology department’s facilities, the ITC has outgrown its “state-of-the-art” label from 40 years ago.

“It can’t handle our electrical needs. It can’t handle our space needs,” Geisinger said. “It’s very tough for us to partner with industry; it’s very tough for us to increase our class size and enrollment because we can’t handle the needs. We don’t have space for students to be in the lab. It’s not conducive for collaborative learning.”

According to Riedle, the ITC has $9.4 million in deferred maintenance. UNI has requested $36.2 million for a renovation and expansion of the building.

“For our students and their education and the industries that we serve with these majors, we need to make some changes within the building,” Riedle said. “The students deserve a space where they can learn what they need to learn to service the industry in Iowa.”